![[field:title/]](/templets/moban/imgcssjs/small-size-of-block-machine202005141501263318703.jpg)

Small Size Of Block Machine

Technical parameter The main parts of machine 1. Belt conveyer 2. Block making machine 3. Pallets feeder 4. Block conveyer 5. Control unit 6. Hydraulic unit 7. Mould 8. Color face device Production Capacity Techinical parameter Technical parameter of our XD3-20 cement brick making machine ♣We...

Technical parameter

|

External Dimension |

1150X1040X1870mm |

|

Vibration Style |

Table mould vibration |

|

Vibration Frequency |

60HZ |

|

Rating Pressure |

8MPA |

|

Pallet Size |

680*540mm |

|

Cycle Time |

20-25sec |

|

Power |

17KW |

|

Weight |

3500kg |

The main parts of machine

1. Belt conveyer

2. Block making machine

3. Pallets feeder

4. Block conveyer

5. Control unit

6. Hydraulic unit

7. Mould

8. Color face device

Production Capacity

|

Name & picture |

Size |

PCS/MOULD |

PCS/HOUR |

|

|

Hollow block |

|

400*200*200mm |

3 |

540 |

|

Porous block |

240*115*90mm |

8 |

1440 |

|

|

Solid brick |

240*115*53mm |

18 |

3240 |

|

|

Holland brick |

200*100*60mm |

10 |

1440 |

|

|

Paving block |

225*112.5*60mm |

10 |

1440 |

|

Technical parameter of our XD3-20 cement brick making machine

|

♣Workshop needed:10m length*6m width ♣Worker:2-3 persons ♣Total investment budget:$12000-$18000 Characteristic Of cement brick making machine √High Technology---Uses Germany Hydraulic Pressure Technology √High Efficiency--4320-25920pcs per day, make profit quickly. √Low power consumption---Totally cost 30KW √Customized demand---Design of best selling bricks in your market √Professional service---Proposal and experienced instruction |

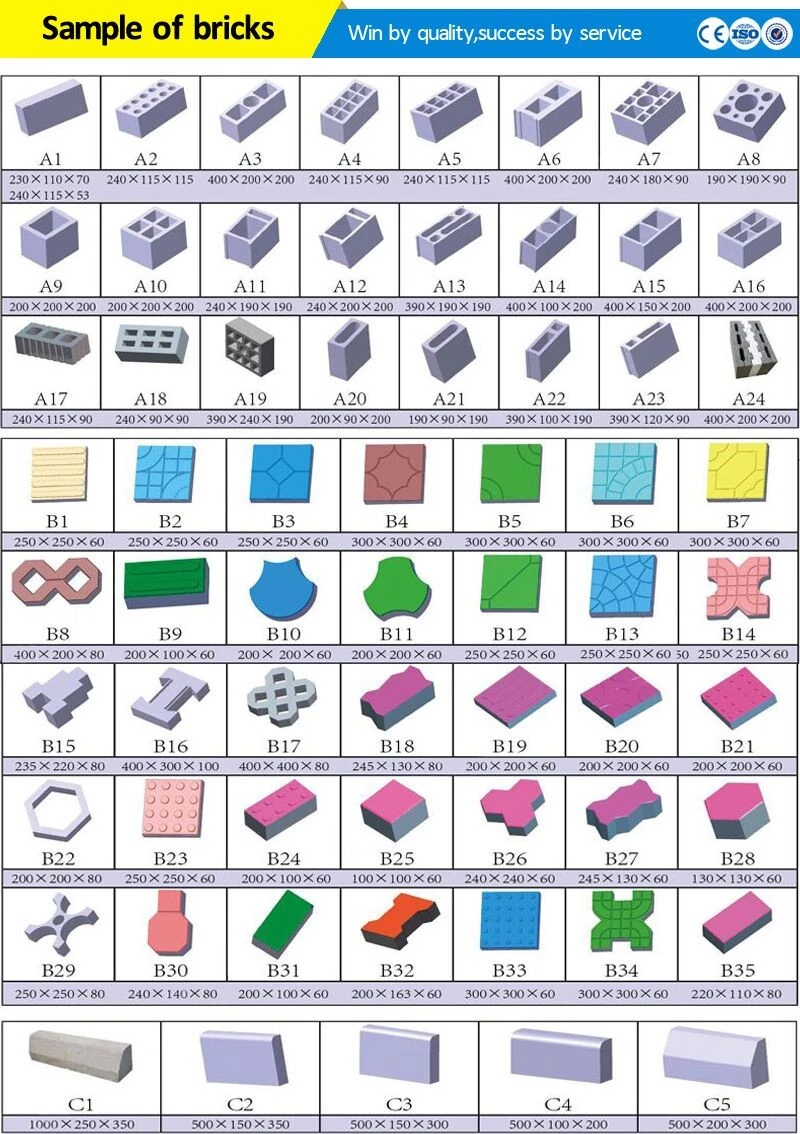

♣We can make different size all kinds construction bricks and blocks, Cos we can

customize the mould based on the design that customer want.

What are the Material ratio:

Cement:8%-10% sand:30%-40% stone:50%-60%

Working process of paving brick manufacturing machine

→1, Mixing the raw material(cement or concrete or fly ash mixture), after getting perfect proportion material, the belt conveyor will deliver the raw material into the stocking bin.

→2, Automatically open the stocking bin gate to feed the material to the feeding car, after getting enough ratio material, will close the gate of stocking bin.

→3, The block conveyor will deliver the pallets, hydraulic press the material and moulding, by press head and mould function, then get the final block.

→4, if need color blocks, by 360 degree no dead angle color feeder, to balance the pigment, then send the brick machine to outlet.

Terms of Payment?

A: Payment:30% by T/T as deposit; remainder 70% to be paid three days before shipment.

When you need our proposal and quotation, what you have to mention in your inquiry?

A: please provide daily capacity, the brick size and you want to build a new brick plant or brick making machinery only. so we can give the proposal and offer accordingly.

What country and regions are your equipment mainly sold into?

A: Our machines were sold into 50 nations and regions, including southeast Asia, Latin-America, middle-east region, Africa and Europe.

What is the role of the stacker?

Stacker can automatically stack, stabilize and save labor.

After-sales service:

24 hours Instant feedback

If you have any questions or problems with the machine, please feel free to contact us , we will provide guidance and solution to customers within 24 hours by email or phone

Provide one-year free warranty and life-long service;

Assist users to formulate production formula;

Set up completed users’ data and provide a better follow-up service;

Supply spare parts and moulds;