![[field:title/]](/templets/moban/imgcssjs/hot-sale-manual-block-machine202005181447222364167.jpg)

Hot Sale Manual Block Machine

Technical parameter Production Capacity Working process of paving brick manufacturing machine →1, Mixing the raw material(cement or concrete or fly ash mixture), after getting perfect proportion material, the belt conveyor will deliver the raw material into the stocking bin. →2, A utomatically...

Technical parameter

|

External Dimension |

1020X1040X2480mm |

|

Vibration Style |

Table mould vibration |

|

Vibration Frequency |

60HZ |

|

Rating Pressure |

8MPA |

|

Pallet Size |

680*540mm |

|

Cycle Time |

20-25sec |

|

Power |

17KW |

|

Weight |

3500kg |

|

|

Production Capacity

|

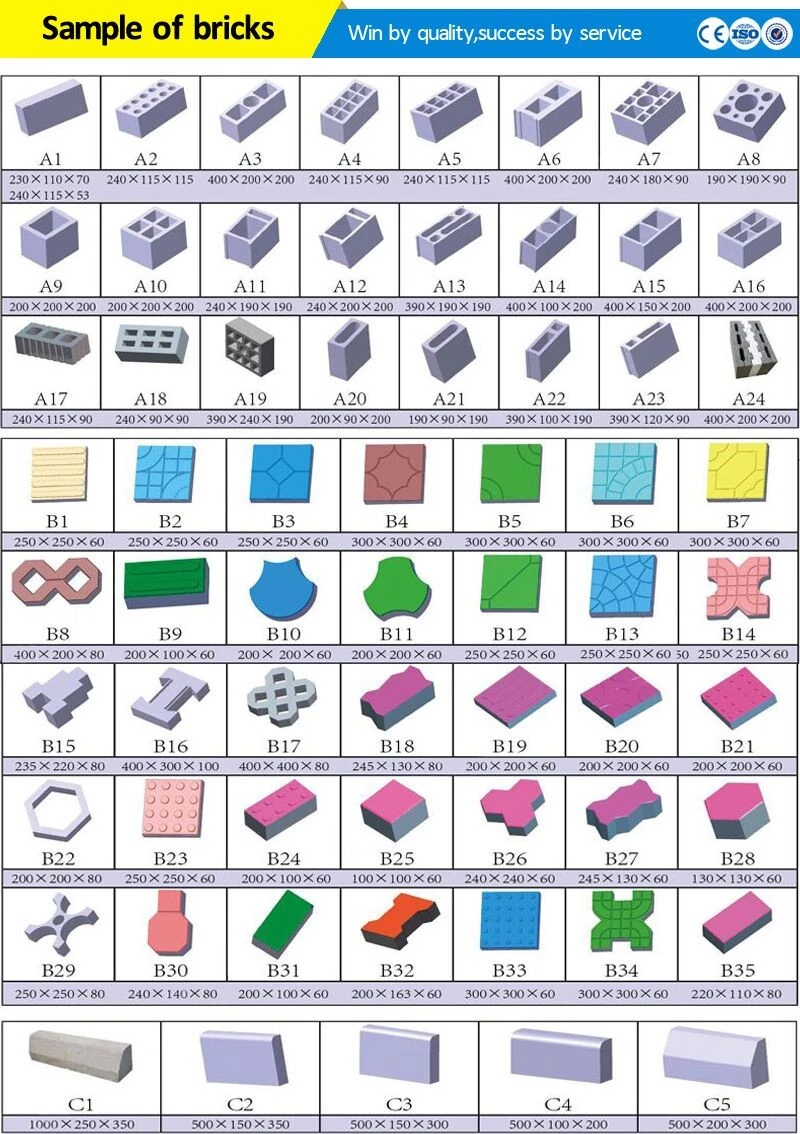

Name & picture |

Size |

PCS/MOULD |

PCS/HOUR |

|

|

Hollow block |

|

400*200*200mm |

3 |

540 |

|

Porous block |

240*115*90mm |

8 |

1440 |

|

|

Solid brick |

240*115*53mm |

18 |

3240 |

|

|

Holland brick |

200*100*60mm |

10 |

1440 |

|

|

Paving block |

225*112.5*60mm |

10 |

1440 |

|

Working process of paving brick manufacturing machine

→1, Mixing the raw material(cement or concrete or fly ash mixture), after getting perfect proportion material, the belt conveyor will deliver the raw material into the stocking bin.

→2, Automatically open the stocking bin gate to feed the material to the feeding car, after getting enough ratio material, will close the gate of stocking bin.

→3, The block conveyor will deliver the pallets, hydraulic press the material and moulding, by press head and mould function, then get the final block.

→4, if need color blocks, by 360 degree no dead angle color feeder, to balance the pigment, then send the brick machine to outlet.

How many labors needed in a production line?

A:It depends on the automation level of the production line. The more automatic the line is ,the less labor the line needs.

B. Are you factory or trading company?

We are factory, you can guaranteed that the quality is good.

Note

The Manual Block Machine features return oil filtration and a separate filtered cooling system with a filtration accuracy of 10 microns. In order to clean the oil and reduce the failure, it is necessary to replace the four filter elements in one filter system in a normal situation. Only the new filter element is allowed to be used, and the old filter element is not allowed to be scrubbed. Filter cartridges must use high quality filter cartridges, such as micro-fine filter cartridges. Applicable to low-cost inferior filter core, not only can not play a role in filtration, but it can damage the press.