![[field:title/]](/templets/moban/imgcssjs/manual-interlocking-block-making-machine51040843814.jpg)

Concrete Block Making Machine

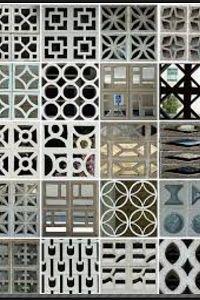

Our XD10-15 breeze block making machine can make all kind of breeze blocks of Australia Technical parameter Main Technical Characteristic ●PLC intelligent control during the whole process is equipped with the data outputted device to realize the ideal man-machine interaction. Control system...

Our XD10-15 breeze block making machine can make all kind of breeze blocks of Australia

Technical parameter

|

External Dimension |

5200X2400X2850mm |

|

Vibration Style |

Table mould vibration |

|

Vibration Frequency |

50-70HZ |

|

Rating Pressure |

20MPA |

|

Pallet Size |

1100*840mm |

|

Cycle Time |

15-20sec |

|

Power |

35KW |

|

Weight |

10500kg |

Main Technical Characteristic

●PLC intelligent control during the whole process is equipped with the data outputted device to realize the ideal man-machine interaction. Control system includes safe logic control and trouble diagnosis system.

●With 4-pole leading mode and super long guide bearing, it can guarantee the accurate motion of indenter and mould. The machine is made from large strong steel, special welding technology and material with sturdy and shakable.

●Using independent hydraulic integrated station, it can avoid the influence of hydraulic system from . the vibration of the main engine to guarantee hydraulic system working reliability.

●Packing box adopts free-swing leading way. It is the best to make mould load reduce packing. Using integrated synchronism vibrating stage to ensure the best shake effect.

●Import computer, electric equipment, weather strip and partial hydraulic elements. The equipments are comprehensive and reliable.

●A machine is multi-purpose, can produce various different specifications through changing mould.

●The adaptability of raw material is good. Advanced vibration shaping technology can mix a lot of various waste dust and residues including slag, gangue, scoria, pumice and stove perlite etc. to make varied medium-grade or high-grade concrete products with load-bearing or non load-bearing.

How about the installation? Can you people to our country to install? How many days will be taken for installation?

1, Detailed time arrangement analysis based on different client as following:

2. Machine standards producing cycle is 25 days (Except client customized need rechange machine configuration) ;

3. Shipping time from China domestic port to client domestic port take about 20-30 days ;

4. Installation and training until machine functioning well take about 10 days

How many labors needed in a production line?

A:It depends on the automation level of the production line. The more automatic the line is ,the less labor the line needs.

What’s the daily capacity of your machine for paver block.

A:It depends, our XD10-15 series machine which was powerful can do 35000 pieces a day.

Are you factory or trading company?

We are factory, you can guaranteed that the quality is good.

Warranty service

Best after-sales service for every customers within one year product warranty.

What is the raw material for paving block brick making machine to produce bricks?

A: cement, lime, concrete, sand, broken stone, mud, gangue, shale etc .

Terms of Payment?

A: Payment:30% by T/T as deposit; remainder 70% to be paid three days before shipment.

When you need our proposal and quotation, what you have to mention in your inquiry?

A: please provide daily capacity, the brick size and you want to build a new brick plant or brick making machinery only. so we can give the proposal and offer accordingly.

What country and regions are your equipment mainly sold into?

A: Our machines were sold into 50 nations and regions, including southeast Asia, Latin-America, middle-east region, Africa and Europe.

What is the role of the stacker?

Stacker can automatically stack, stabilize and save labor.