![[field:title/]](/uploads/allimg/c211020/1634E19C45120-S5K3.jpg)

Soil Block Making Machine

XD6-15 is full-automatic block production line, it is composed of cement silo, batching machine, mixer, belt conveyor, host machine, and stacker. It have following features: ♦1. XD6-15 is a multifunction automatic block machine, it can produce many kinds of hollow blocks, solid blocks, curbstone...

XD6-15 is full-automatic block production line, it is composed of cement silo, batching machine, mixer, belt conveyor, host machine, and stacker. It have following features:

♦1. XD6-15 is a multifunction automatic block machine, it can produce many kinds of hollow blocks, solid blocks, curbstone and paver just by changing the mould.

♦2. The block moulds are made of 16# manganese steel. Besides the good raw material, precise line cutting technology and 900℃ carburizing heat treatment technology are all adopted in the process of brick moulds production. Then the mould size error can be controlled within 0.002mm . The surface layer of the brick moulds get higher hardness (achieving HRC54-58) and better wear resistance.

♦3.The machine adopts hydraulic moulding technology, it can assure the block machine have stable and high-efficiency working status, and the blocks produced are of better quality, larger density and higher strength.

♦4.The machine is equipped with Japan Omron switches and Siemens motor. We select original Mitsubishi PLC control program to assure the block machine has a stable and high-efficiency working status.

♦5.XD6-15 is full-automatic production line. It can produce 5000-50000pcs blocks per shift. The capacity varies according to the size and type of the brick.

Main technical parameters | |||

Dimension of host machine | 3500*1700*2930mm | Host machine power | 29.1KN |

Weight of host machine | 8.0T | Mixer model | JS500 |

Molding area | 861*880mm | Vibration force | 50-60KN |

Water consumption | 5-8T/Day | Workshop | 260㎡ |

The size of the pallet | 830*940*25mm | ||

Theoretical production capacity | |||

Size(L*W*H) | Pcs/Mould | Pcs/Hr | Pcs/8Hr |

400*100*200mm | 12 | 2160*2520 | 17280-20160 |

400*150*200mm | 8 | 1440-1920 | 11520*15360 |

400*200*200mm | 6 | 1080-1260 | 8640-10080 |

400*250*200mm | 4 | 720-840 | 5760-6720 |

230*110*70mm | 30 | 5400-6300 | 43200-50400 |

Paver:200*100*60mm | 24 | 4320 | 34560 |

Paver:200*163*60mm | 16 | 2880 | 23040 |

Detailed Image

Control center

Best components is used in control system, Panasonic PLC and Schneider relay were used in this machine.

Hydraulic system

The machine adopts hydraulic moulding technology, it is easy to operate and the blocks produced are of better quality, larger density and higher strength.

Mould

The mould adopts precise wire cutting technology to reduce error and heat treatment technology to prolong its service life.

Link section

Perfect link to ensure the stable operation and service life of the machine

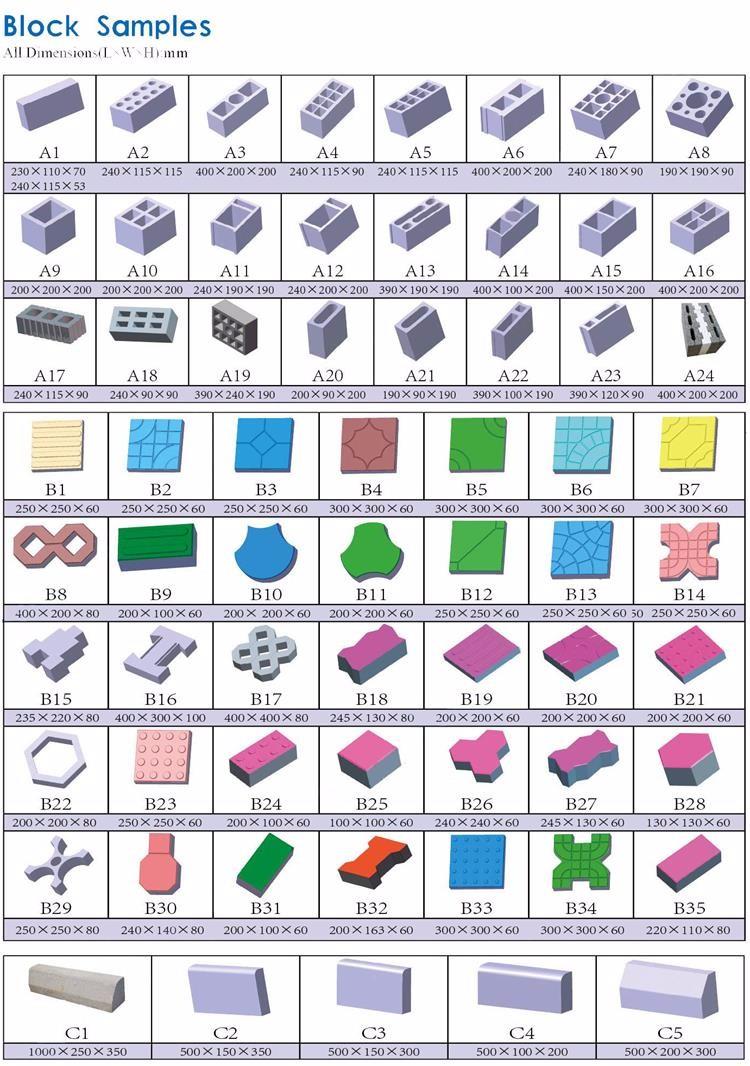

Product Sample

XD6-15 full-automatic concrete block making machine production line can produce many kinds of hollow bricks ,solid bricks, curbstone and paver just by changing the mould.

Packing & Delivery

Shipment: 20-40 days after receive the receipt of deposit

Supports various modes of transportation

Our Service

* Pre-sales Service

(1) Professional suggestions (raw material matching, machine selection, the condition of building factory, Feasibility analysis for brick machine production line).

(2) Device model choice (recommend the best machine according to the raw material, capacity and the size of brick).

(3) 24 hours on-line service.

(4) Welcome to visit our factory and production line anytime.

(5) Introduce the company file, product categories and production process.

(6)Sample testing support.

* Sale:

(1) Update the production scheduling in time.

(2) Quality supervision.

(3) Product acceptance.

(4) Shipping on time.

* After-sale:

(1) Training how to install the machine, training how to use the machine.

(2) Engineers available to service machinery overseas.

(3) Recall clients regularly , get feedback in time,keep well communication with each other.