![[field:title/]](/uploads/allimg/c211020/1634E2BR0940-4L926.jpg)

Zenith Hollow Block Machine

block bricks machine 3-15 block bricks machine Technical Parameters Capacity Feature and Advantage We used the Rubber pad (PU) under the Shaking box, Can reduce the noise when the machine working. More Stably. Product application scenarios Packaging & Shipping Packaging:standard Container,...

Zenith Hollow Block Machine

zenith Hollow Block Machine QT8-15/ XD8-15

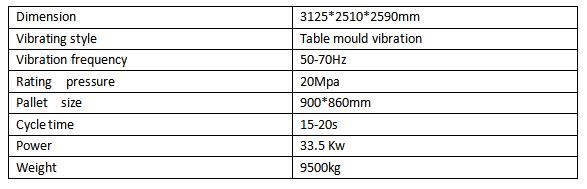

Technical Parameters

Capacity

Feature and Advantage

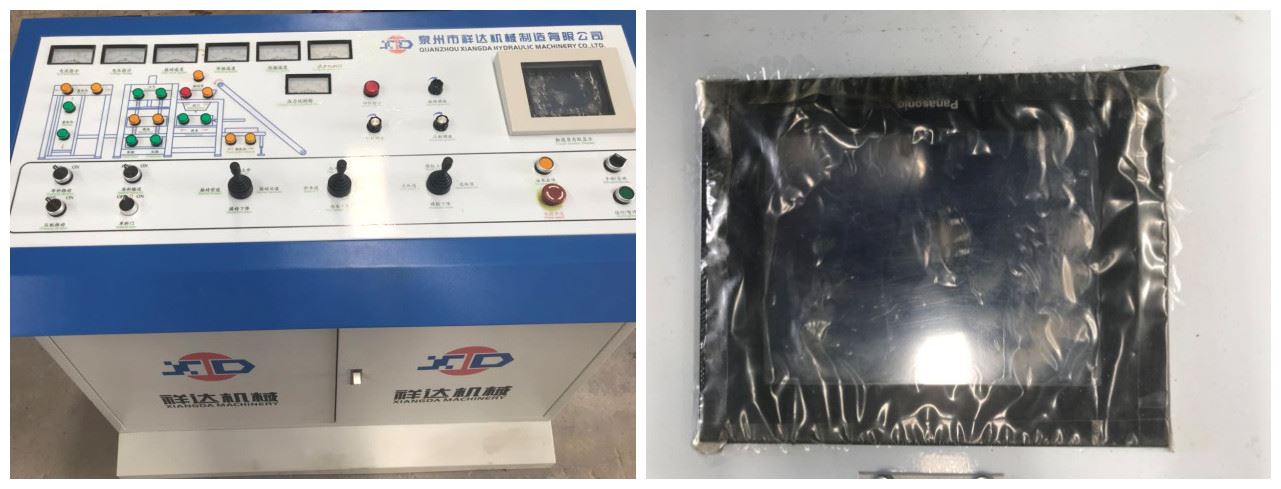

zenith Hollow Block Machine QT8-15/ XD8-15 revetment block making machine is an integration of mechanical, electric and hydraulic technologies; The whole set of equipment adopts Siemens PLC control system and synchronous or asynchronous hydraulic; process can be automatically continuously completed: feeding, special distribution device, conveyor panel, lifting die and lowering die, vibration, and carrying, all these processes are all automatic.

when the machine working, the Rubber pad (PU) which under the Shaking box, can reduce the noise and be more Stably.

The system could control easily and PLC intelligent control during the whole process. fully equipped with complete functions, strong applicability, and easy to learn and use, Has the overload alarm system, Make sure the safety and stability and has a hardware failure self-detection function, which can send out alarm information in time when a failure occurs.

Product application scenarios

Our customers in Oman use Hollow Block Machine QT8-15/ XD8-15 to produce a variety of hollow wall and pavement bricks.

FAQ:

1.How to sure your brick making machine quality ?

Our machine use high-strength steel structure,the total weight much more than others,mould are made by heat treatment and line cutting can use 30 million times.

2.How about the brick machine price ?

The showing price only for reference,please sent us inquiry email,we will send you the quotation with better price .

3.What are the features of automatic production line, semi-fully automatic production line and fully automatic production line?

Automatic production line: it requires 10-12 workers, generally using bagged cement, without cement metering system and centralized control system, with low automation. Natural conservation;

Semi-fully automatic production line: it requires 8-10 workers, uses bulk cement, it has cement metering system and centralized control system, and has a high degree of automation. Natural conservation;

Fully automatic production line: it requires 3-5 workers, automatic batching - weighing - mixing - brick making, automatic transfer - curing- cubing, pallet recycling, production automation, natural curing or steam curing. However, the input cost is relatively high.

About us

Quanzhou Xiangda Machinery Manufacture Co., Ltd. is a professional high-tech enterprise for concrete block making, owning R&D, manufacturing,sale and after-sale service

Our main products as flws:concrete block machine. Composite insulation wall panel machine, Permeable brick production line, Automatic palletizing system, paving block and curbstone machine, mixer batching plant and other construction machinery.

*We strictly obey the latest standard in block making industry.

*We have passed QM ISO9001:2000 and CE. Our products are popular for its stable quality and high tech.