![[field:title/]](/templets/moban/imgcssjs/granite-cone-crushing-plant-crusher-machine46148673476.jpg)

Granite Cone Crushing Plant Crusher Machine

Product Introduction: Granite cone crushing plant is mainly composed of vibrating feeder, jaw crusher, impact crusher, vibrating screen, belt conveyor and centralized electronic control. The designed output is 50-800t/h and cone crusher and dust removing equipment can be equipped to satisfy...

Product Introduction:

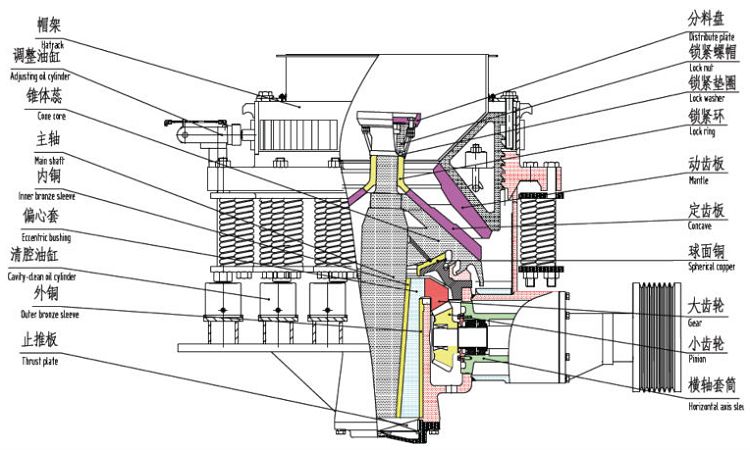

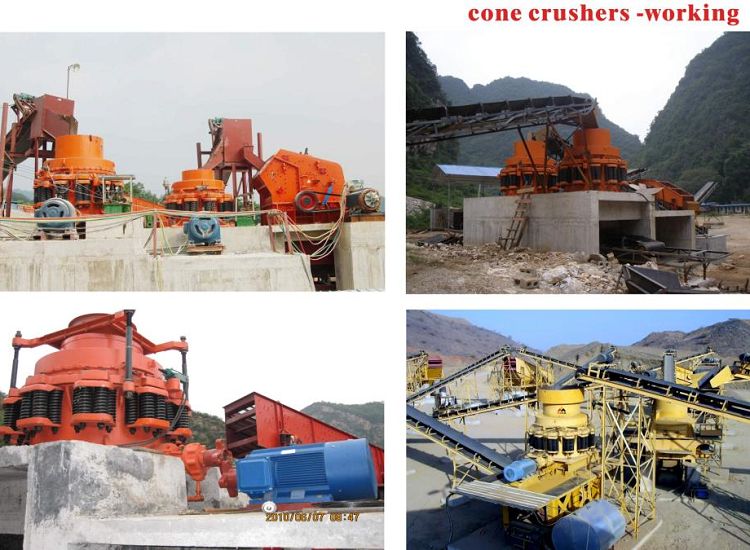

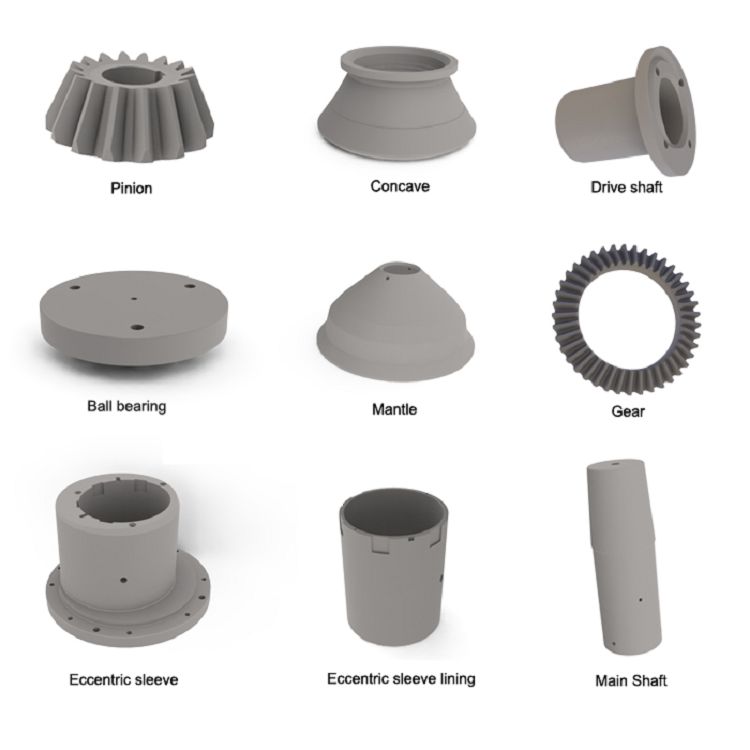

Granite cone crushing plant is mainly composed of vibrating feeder, jaw crusher, impact crusher, vibrating screen, belt conveyor and centralized electronic control. The designed output is 50-800t/h and cone crusher and dust removing equipment can be equipped to satisfy different processing needs of the customers.

Granite Cone Crushing Plant Crusher Machine advantages:

1. All three screens are adjustable to enable production of varying gradings.

2. Once sized, products are segregated by two side discharge conveyors which eliminate contamination.

3. Variable amplitude on the feeder and grizzly ensures maximum efficiency regardless of the feed material.

4. Variable speed vibrating feeder provides for optimum control to deliver maximum production at all times.

5. Both side conveyors can fold up manually for transport.

6. Rock screen does not require a dedicated operator, which further reduces overheads and running costs

7. Tipping of the primary grizzly is by remote control from the loader.

8. All safety protection shutdowns and guarding are fitted as standard to meet safety regulations.

|

Equipment |

Model |

Qty (set) |

Capacity (t/h) |

Power (kw) |

Weight (t) |

Dimension (mm) |

|

Vibrating Feeder |

GZD300*90 |

1 |

80-100 |

2*2.2 |

1.5 |

3400×1020×900 |

|

Jaw Crusher |

PEV500*750 |

1 |

45-100 |

55 |

12 |

1800×1796×1940 |

|

Symons Cone Crusher |

WKS-90 |

1 |

50-100 |

75 |

9.97 |

2865×2000×2190 |

|

Vibrating Screen |

3YK1848 |

1 |

32-276 |

18.5 |

6 |

5900×2560×1650 |

|

Belt Conveyor |

B650/B500 |

6 |

7.5/5.5 |

Packaging and Shipping

Packaging:standard Container, Nude Packs or in Bulk.The electrical motor or spare parts will be packed by wooden case or steel frame.Unique offers various ways of package, fumigation-free wooden cases, steel plate cases, or as the clients' request. Most of the time, the equipment will be loaded to the containers in the factory. Unique workers make sure all equipment are steady and fixed before close the door of the container, there will be no damage during transporation and shipment.

We promise that the cone crusher will be shipped to you timely and safely.

After-sales service support

1.more than 12 months' warranty period

2.Erection and Commissioning

3.Operator Training

4.Spare Parts Supply

Normally,Equipment spares will be offered with manufacturing cost in at least 10 years since the order is placed. To establish long term cooperation, we will regularly call and email our clients, to check the equipment working condition, offer suggestions for maintenance, and if necessary we will pay a visit to clients to solve the problems caused during equipment working.

Our Advantages---

A.We have over 30 years experiences of manufacturing crushers, crusher line and other mining equipments.

B.Our new wearable material ensures the working life of plate hammer, impact plate and liner board much longer.

C.Our even plate structure makes final material smaller and cubic, no inner crack.