![[field:title/]](/templets/moban/imgcssjs/mobile-diesel-jaw-stone-crusher-equipment59298621175.jpg)

Mobile Diesel Jaw Stone Crusher Equipment

Product Description Mobile diesel jaw stone crusher Equipment provides a new field of business opportunities for contractors, quarry operators, recycling and mining applications. It offers high efficient and low cost project plan without environment limit for the client. Mobile diesel jaw stone...

Product Description

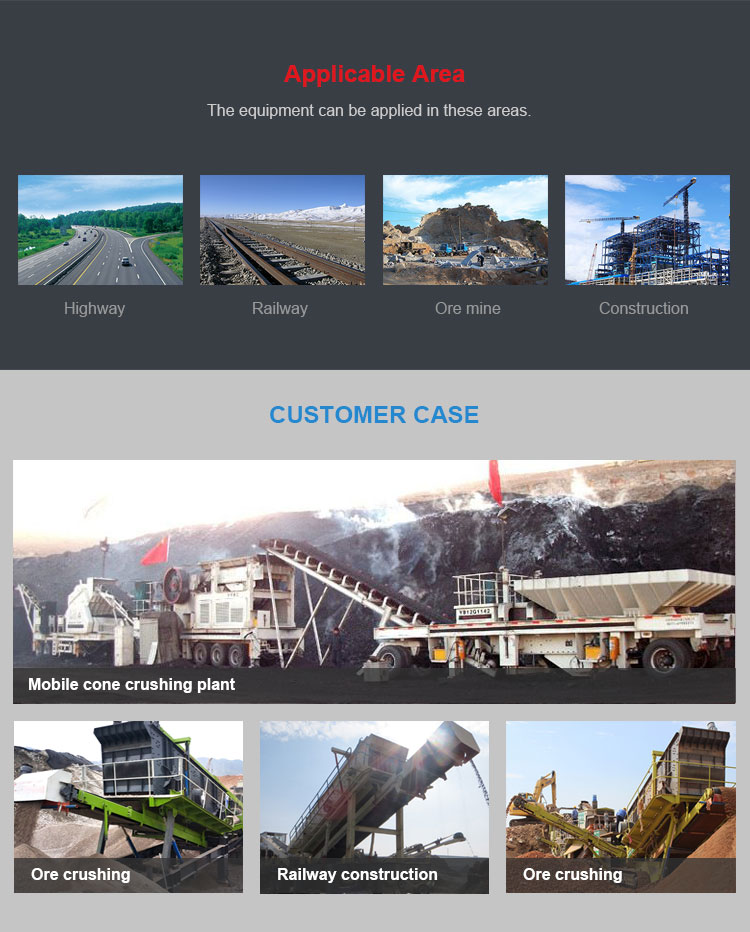

Mobile diesel jaw stone crusher Equipment provides a new field of business opportunities for contractors, quarry operators, recycling and mining applications. It offers high efficient and low cost project plan without environment limit for the client.

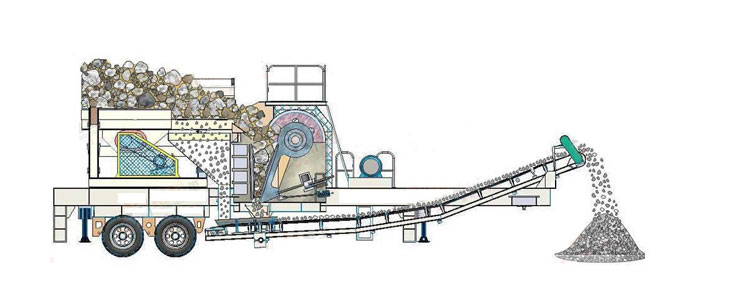

Mobile diesel jaw stone crusher is stone crusher on movable vehicle. This series of Mobile stone incorporates all the equipments together on one truck, which has high chassis, narrower body compared with other trucks, this ensure the crushing plant be easily transported on highways and moved to crushing sites, so it is able to achieve on-site crushing without material transporting from one place to another place. In addition, the lengthened plant is able to transport the final products to the motor-lorry directly. it can start to work soon even in the bumpy ground without reinstallation, so it saves more time and money than fixed crushing plant which needs to install individual equipment one by one.

Worry-saving for rapidly putting into production, money-saving for flexibility and environmental protection:

Compared with fixed production line, mobile diesel jaw stone crusher has a shorter engineering period and rapider transition and follow-up, which not only reduce the investment risk and opportunity cost of the investors, but also avoid the demolition and construction after the end of project, making it more economical and environmentally protective; in addition, the machine has excellent depreciation hedging capacity, so that the investor can rapidly invest in new project, or sell the machine to get money, thus reducing the investment cost.

Project Case

50TPH Hard Aggregate Crushing Production Line in Philippines:

With the rapid growth of world economy, every country starts to focus on the infrastructure construction. To adapt for the modernization of infrastructure, the demand for aggregate production is expanding.

Equipment configuration advantage:

1. Integrated Complete Set of Mobile Crushing Station.

The installation of integrated set frees customers from infrastructure construction on complicated terrains. It not only reduces the material consumption and construction period, but also occupies smaller floor area.

2. Mobile Crushing Station Reducing Material Transportation Expenses.

Mobile crushing station can directly crush materials on customer sites, which avoids the step of material transfer, greatly reducing material transportation expenses.

3. Mobile Crushing Station is Flexible.

It is easy for mobile crushing station to travel on ordinary roads and the rugged roads. So it saves time for entering the construction sites quickly and offers more flexible space and rational layout arrangement in the whole crushing process.

4. Mobile Crushing Station Has High Adaptability and Free Collocation.

As for screening system of coarse and fine crushing, single unit can work independently. Several machines freely collocated to form a system to process materials is also available. The discharging hopper offers flexibility of multiple collocations to the screening material transportation means.

5. Mobile Crushing Station Can Work Directly and Effectively.

The integrated mobile crushing station can work independently. In terms of the customers’ demands for material types and finished product standards, the more flexible collocation of technologies is offered to meet various requirements of mobile crushing and screening.

6. The performance is more reliable and the maintenance is easier.

The performance of the integrated mobile crushing station is stable while the operation cost is low. The shape of discharging materials is uniform. Besides, it is easy for repair and maintenance because of the simple structure.

Packaging & Shipping

Ways of Packing:

1. Sand blasting, coat with high quality paint;

2. Product wrap by PP-Bubble;

3. Load container, Spear Parts in wooden case.

Transportation:

1. By sea Freight;

2. MSK/MSC/APL/EMC/WANHAI/KLINE;

3. We will remind you before boat arrival.