![[field:title/]](/uploads/allimg/c211020/1634EG9ET20-205D1.jpg)

Combined Cone Crusher Equipment

MPH Combined Cone Crusher Equipment ◆New special design, simple and reasonable structure, smooth and stable running and low operation cost. ◆Cane frame is cast steel structure: High pressure points are reinforced by hard steel, ◆Each side of drive-shaft is equipped with roller bearings. Bearing...

MPH Combined Cone Crusher Equipment

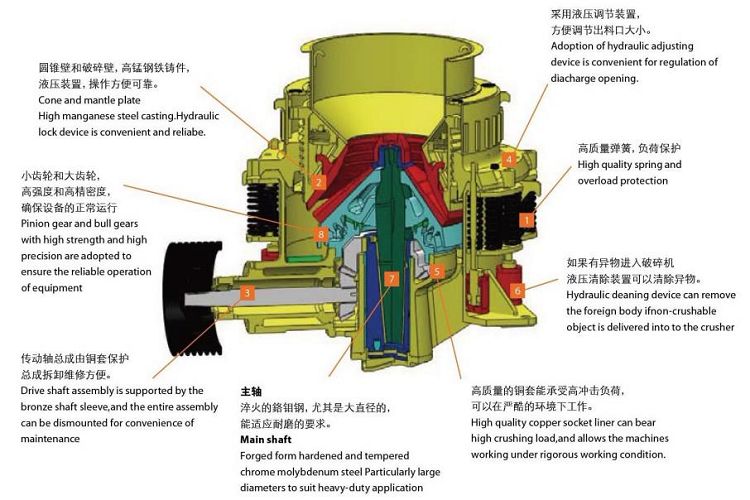

◆New special design, simple and reasonable structure, smooth and stable running and low operation cost.

◆Cane frame is cast steel structure: High pressure points are reinforced by hard steel,

◆Each side of drive-shaft is equipped with roller bearings. Bearing base uses seal ring to prevent lubricating oil leakage.

◆Hydraulic adjustment devices. Convenient to adjust discharge opening size.

◆Hydraulic release system consists of several hydraulic cylinders. Easy to release jammed materials.

◆"Spring type" over-load protection. This release system allows uncrushable materials to pass through without causing damage.

◆A complete lubricating oil circle system, including oil pump , oil reserve tank, oil pipeline , etc. If oil temperature is over high or oil flows slowly, the machine can be shut down automatically. This protection extends crusher's service life.

working principle:

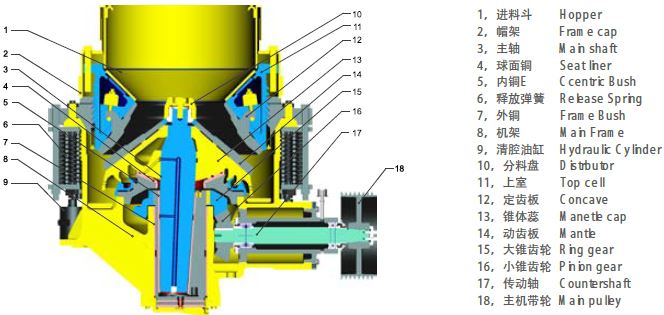

Cone crusher is mainly used for the second stage and subsequent crushing work. At the center of the main shaft in the center of the body, a cone-shaped vertebral body core and a movable tooth plate are installed, and the spherical surface of the vertebral body core is placed on an eccentric seat. Since the center hole and the body hole of the eccentric seat are eccentric, the rotation of the eccentric seat causes the main shaft to rotate.

Below the upper chamber is a fixed tooth plate, which together with the movable tooth plate constitutes a crushing chamber. The feeding platform ensures that the materials fall evenly in the center of the distribution tray. The rotary motion ensures that the materials fall into the crushing chamber evenly. The material is continuously discharged after being crushed. The upper frame connected to the upper chamber and the fixed-tooth plate is mounted on the body through a peripheral release spring. If the material is mixed with particularly hard foreign objects (such as iron blocks), the upper shelf will float under the action of the release spring to let the foreign objects pass through to prevent overload or damage to the machine. After the foreign body passes, it will be restored and the normal crushing work will continue.

Technical date of Combined Cone Crusher Equipment

Model | Chamber | Cone Diameter (inch)(mm) | Max. Feed Size(mm) | Min of discharge Size in(mm) | Weight (t) | Main Motor Power(kw) | Capacity(t/h)in different discharge sizes(mm) |

MPH1300 | C M F | 51" 1296 45" 1143 45" 1143 | 200 150 102 | 16 13 10 | 23 23 23 | 132-160 132-160 132-160 | 135 160 180 200 290 350 105 125 135 160 180 80 105 135 140 |

MPH1400 | C M F | 54" 1372 54" 1372 54" 1372 | 215 160 115 | 19 16 13 | 27 27 27 | 185-220 185-220 1185-220 | 180 220 270 350 440 160 180 200 230 150 195 220 240 |

MPH1600 | C M F | 60" 1524 60" 1524 60" 1524 | 235 175 130 | 22 19 13 | 37.8 37.8 37.8 | 220-250 220-250 220-250 | 230 265 330 450 520 570 215 240 270 330 180 210 240 265 285 |

MPH1700 | C M F | 66" 1676 66" 1676 66" 1676 | 267 203 140 | 22 16 13 | 44.3 44.3 44.3 | 250-300 250-300 250-300 | 330 390 500 650 725 240 250 280 330 190 220 260 330 |

Q1.Can you test our samples?Do you provide beneficiation flow chart?

Yes. You can send your samples to us for test and analysis. Our experienced engineers are specialized in designing process flow for various ores beneficiation, including iron ore, tin ore, copper ore, gold ore, lead zinc ore, manganese ore, etc.

Q2. If I need the complete crushing plant can you help us to build it?

Yes, we can help you combine a complete crushing line and give you related professional advices as long as you need. We had already build many mining projects in China & Overseas.