![[field:title/]](/uploads/allimg/c211020/1634EPZ30310-1363P.jpg)

Non-ferrous Metal Ore Crusher Machine For Sale

Description Heavy Hammer Counterattack is one of the crushing equipment and is a relatively advanced technology in the hammer crusher series in the industry. It adopts advanced production technology to realize one-time feeding molding, which is characterized by high efficiency, energy saving and...

Description

Heavy Hammer Counterattack is one of the crushing equipment and is a relatively advanced technology in the hammer crusher series in the industry. It adopts advanced production technology to realize one-time feeding molding, which is characterized by high efficiency, energy saving and environmental protection. The material can be adjusted according to the demand, and there are coarse, medium, fine and various specifications to choose from. The material has the characteristics of no flake, no smooth body, multi-angle and multi-edge, which can maintain the compressive strength, and is especially suitable for highways, buildings and large-scale engineering materials.

Model | Rotor (Diameter x Lengh) (mm) | Feeding size (mm) | Final products (mm) | Capacity(t/h) | Motor power (kw) |

0806 | 800×600 | ≤300-400 | 0-40 | 60 | 55 |

0808 | 800×800 | ≤400-500 | 0-50 | 80-100 | 75 |

1008 | 1000×800 | ≤500-650 | 0-60 | 100-120 | 90 |

1010 | 1000×1000 | ≤600-750 | 0-70 | 120-150 | 132 |

1210 | 1200×1000 | ≤650-800 | 0-70 | 150-200 | 160 |

1510 | 1500×950 | ≤800 | 0-80 | 160-250 | 110×2 |

1512 | 1500×1230 | ≤800 | 0-80 | 250-300 | 132×2 |

1615 | 1650×1532 | ≤900 | 0-80 | 300-380 | 200×2 |

2015 | 2000×1500 | ≤1200 | 0-80 | 400-500 | 400 |

Advantages

Heavy Hammer Counterattack drives the rotor to rotate at high speed through the belt. When the material enters the working area of the hammer, the rotary hammer crushes them at high speed.

The quarrying machine can adjust the gap between the hammer head and the lining column to change the material particle size to meet the requirements of customers in different places. The head is the main part of the device and is pressed from the alloy.

Its back plate is similar in shape to the slab, which is 13 manganese steel. The input is small, but the effect is very fast.

Packaging & Shipping

1. Container Loading: N*40HQ ,We can use a variety of ways to transport, in full accordance with the requirements of customers

2. Packing Terms: In Nude.

3. Payment Terms: T/T 30% in advance, balance to be paid before shipment by T/T or L/C.

4. Production Lead Time: About 25-30 working days

5. Logo and color: as per customer's requirement.

6. Warranty: 12 months excluding spare parts.

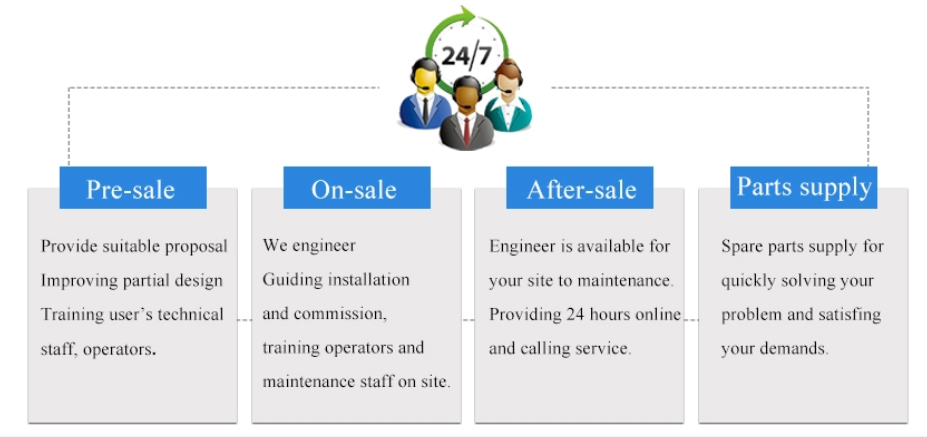

7. We will send engineers to your site, guiding installation, commissioning and operators' training.

And provide instruction manual, installation drawing, electricity map and online technical guiding services.

8. Documents provided for customs clearance: Bill of Lading, Commercial Invoice, Packing List, the Certificate of Origin and other documents required.

Successful Partner

Our customers have been around the world in many countries, worthy of your choice!

Our Services

1.According to your inquiry, the first time to give the offer, the first time to give production.

2.Best After-sales: We will send the technical personnel to the site for installation, commissioning and training work.

3.Warranty period 12 Months, in addition to the force majeure and man-made factors, the damage caused by design, process and manufacturing equipment, the seller is responsible for sending people to offer free repair.

4.We will send the spare parts of concrete mixer plant as soon as possible when necessary, equipment repair parts provided by the seller are original, authentic, quality goods.