![[field:title/]](/uploads/allimg/c211020/1634EM603X20-C195.jpg)

Rock Crushing Equipment

Rock crushing machine price, Rock crushing equipment 1. Rock crushing equipment. za can energy-Saving about 20%~35%. 2. Most professional jaw crusher. 3. Stable performance. 4. Most Competitive Price. Jaw crusher rock crushing machine price, rock crushing equipment Technical data of rock...

Rock crushing machine price, Rock crushing equipment

1. Rock crushing equipment. za can energy-Saving about 20%~35%.

2. Most professional jaw crusher.

3. Stable performance.

4. Most Competitive Price.

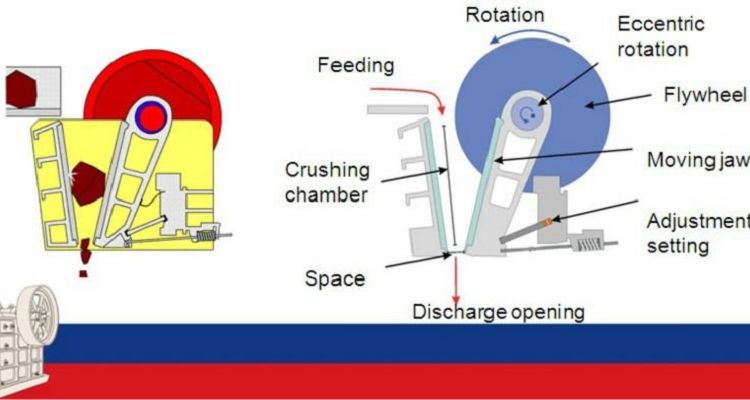

Jaw crusher

rock crushing machine price, rock crushing equipment

Rock crushing machine price, rock crushing equipment |

Position in a crusher production line |

Primary crusher |

Feed opening (mm) |

250*1000 -- 1100*1200 |

Maximum feeding size (mm) |

220-930 mm |

Range of discharge opening (mm) |

20-275 mm |

Capacity (t/h) |

15-650 |

Power (kw) |

30-185 |

Fields Of Application |

ore crushing, construction aggregate production, construction waste crushing, water conservancy and Hydropower Engineering, highway, railway, road and bridge construction and other industries rock crushing equipment.za. |

Application |

granite, marble, basalt, limestone, quartz, cobble, iron ore, copper ore, and some other mineral &rocks rock crushing equipment.za. |

Brief introduction |

rock crushing equipment.za is commonly known as European jaw crusher, and is a new type of crusher developed by our company after the release of traditional jaw crusher. stone crusher machine price is a perfect combination of modern science and technology and the production practice, which can better satisfy the automatic production demands of vast customers. rock crushing equipment.za |

Features |

1. V-shaped structure crushing cavity is able to meet a big feeding. |

Technical data of rock crushing machine price, rock crushing equipment

Model | Feed opening (mm) | Maximum feeding size (mm) | Range of discharge opening (mm) | Capacity (t/h) | Speed (r/min) | Power (kw) | Overall dimension (mm) |

PEW250×1000 | 250×1000 | 220 | 20-40 | 15-50 | 330 | 30 | 1400×1850×1310 |

PEW250×1200 | 250×1200 | 220 | 20-40 | 20-50 | 330 | 37 | 1400×2050×1310 |

PEW400×600 | 400×600 | 350 | 35-85 | 15-70 | 250 | 37 | 1920×1460×1840 |

PEW760 | 760×1100 | 640 | 75-200 | 150-350 | 270 | 110 | 2600×2500×2200 |

PEW860 | 860×1100 | 720 | 100-225 | 200-500 | 240 | 132 | 3300×2320×3120 |

PEW1100 | 1100×1200 | 930 | 150-275 | 300-650 | 210 | 185 | 4140×2660×3560 |

Application case of rock crushing machine price, rock crushing equipment

Click for More Information!!!

Excellent model customer case of SBM Factory 2018 new products stone crusher machine price

250TPH Granite Tailing Crushing Line

Project BackgroundWith the construction of more and more high-standard buildings, the quality requirements for concrete in the market are getting stricter

Design Scheme

Material: Granite tailing

Finished Product: High-quality aggregate and machine-made sand

Output Size: 0-5-10-31.5mm

Capacity: 250TPH

Equipment: F5X1345 Vibrating Feeder, PEW860 European Hydraulic Jaw Crusher, HST250 Single Cylinder Hydraulic Cone Crusher, VSI6X1150 Centrifugal Impact Crusher, S5X2460-2, S5X2460-3 Vibrating Screen.

Recommended Equipment

HST Series Single Cylinder Hydraulic Cone Crusher

HST series single cylinder hydraulic cone crusher is a new type high-efficiency cone crusher independently researched, developed and designed by SBM through summarizing over twenty years of experience and widely absorbing the advanced cone crusher technologies in America and Germany. This cone crusher integrates mechanical, hydraulic, electrical, automation and intelligent control technologies, and represents the advanced cone crusher technology in the world.

[Input Size]: 10-560mm.

[Capacity]: 30-1000t/h.

[Application]: Aggregate and metallic ore crushing.

[Material]: Hard materials such as pebble, limestone, dolomite, granite, rhyolite, diabase, basalt, ferrous and non-ferrous metal ores.

S5X Series Vibrating Screen

SBM's S5X series vibrating screen is of high vibration intensity. Under the same specifications, it has larger processing capacity and higher screening efficiency compared to traditional screens. It is particularly applicable to heavy type, middle type and fine screening operations, and it is the ideal screening equipment after primary crushing, secondary crushing and for finished materials.