![[field:title/]](/uploads/allimg/c211020/1634ETb34J0-94F0.jpg)

Cone Crushing Machine

High-efficiency cone crushing machine Product Description High-efficiency cone crushing machine applications Introducción CS series cone crusher apply to crushing super hardness materials whose compressive strength is above medium hardness, such as granite, basalt, quartzite, iron ore, cobble...

High-efficiency cone crushing machine

Product Description

High-efficiency cone crushing machine applications

Application Material | Granite, limestone, marble, river stone, barite, basalt, bentonite, calcite, calcium carbonate, coal, dolomite, feldspar, gravel, gypsum, micro silica, pebble, quartz, slag and so on |

Capacity(t/h) | 30-800 t/h |

Input Size | 200-1000mm |

Output Size | 0-5mm. 5-10mm, 10-20mm |

Introducción

CS series cone crusher apply to crushing super hardness materials whose compressive strength is above medium hardness, such as granite, basalt, quartzite, iron ore, cobble stone, etc. The cone crusher is mainly used in mining,building material, metallurgy industry, sandstone processing, road and bridge engineering, etc.

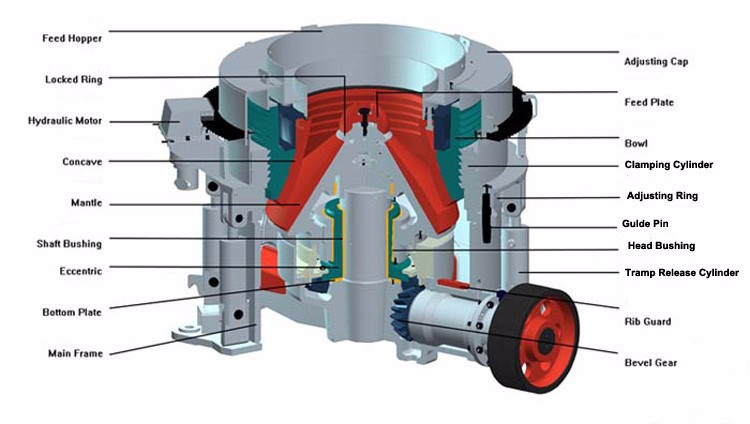

Working principle

Cone crusher consist of frame, transmission device, hollow eccentric shaft, bowl-shaped bearing, crushing cone, springs and hydraulic pressure station for adjusting discharge opening. During operation, the motor drives the eccentric shaft shell to turn around through a horizontal axle and a pair of bevel gear. The axle of crushing cone swings with the force of eccentric shaft shell so that the surface of the crushing wall is close to the roll mortar wall from time to time. In this way, the ores and rocks will be pressed, crooked and crushed.

Feature

1. Good material particle size.

2. Low maintenance costs.

3. Hot selling all over the world.

4. National patent.

Our Services

Pre-sale services, we do

Act as a good adviser and assistant of clients; enable them to get rich and generous returns on their investments.

1. Select equipment model;

2. Sdeign and manufacture products according to clients' special requirement;

3. Train technical personnel for clients.

Services during the sale, we do

Respect clients; devote ourselves to improving the total value of clients.

1. Pre-check and accept products ahead of delivery.

2. Help clients to draft solution.

After-sales service, we do

Provide considerate services to minimize clients' worries.

1. Assist clients to prepare for the first construction scheme;

2. Install and debug the equipment;

3. Train the first-line operators on site;

4. Examine the equipment regularly;

5. Take initiative to eliminate the troubles rapidly at site;

6. Distribute the guarantee fittings door-to-door;

7. Provide perfect service;

8. Provide technical exchanging;

9. Provide maintenance for big items.