![[field:title/]](/uploads/allimg/c211020/1634EYV59C0-E244.jpg)

Mobile Stone Impact Crusher

Product Description Features: Mobile stone impact crusher, which can also be called rock crushing plant, includes vibrating feeder, jaw crusher, impact crusher or cone crusher, vibrating screen, belt conveyor and centrally electric controlling system, etc. The designed capacity is from 40t/h to...

Product Description

Features:

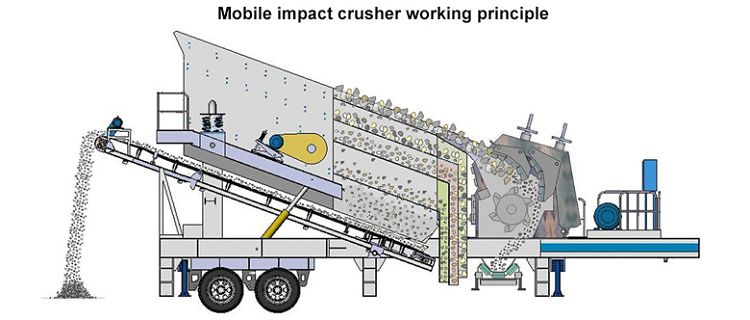

Mobile stone impact crusher, which can also be called rock crushing plant, includes vibrating feeder, jaw crusher, impact crusher or cone crusher, vibrating screen, belt conveyor and centrally electric controlling system, etc. The designed capacity is from 40t/h to 600t/h. To meet customer’s specific requirement for stone crushing, we can also add other equipment such as cone crusher, dust catcher in the crushing plant.

1. High performance jaw crusher, impact crusher and cone crusher;

2. Feeder, belt conveyor and vibrating screen are all in one;

3. Turn axle of traction is convenient for road transit and deeping into the working place;

4. Vehical installation supporting is easier for equipment to station in the working place;

5. Vehical electric generating set, motors and control box are all included.

Components of Our Mobile stone impact crusher | |

1. | Traveling Chassis |

2. | Primary crusher (Jaw Crusher) |

3. | Secondary crusher (Impact crusher or Cone Crusher) |

4. | Triple-Deck Vibrating Screen and Belt Conveyor |

Application of Our Mobile stone impact crusher | |

1. | Stone Quarry Site |

2. | Road Construction |

3. | Railway Engineering |

4. | Construction waste crushing |

5. | Rock & Mineral Operations |

Advantages of Mobile Mobile stone impact crusher

Technical Parameters Easily setup;

Low cost ;

High efficient;

Quick road transportation;

Incorporated & Smart design;

High crushing ratio, powerful crushing.

Technical Parameters

Parameters of Mobile stone impact crusher

Model | MSTF1010 | MSTF1210 | MSTF1214 | MSTF1315 |

Vibrating feeder | 3YA1548 | 3YA1854 | 3YA1860 | 3YA2160 |

Impact Crusher | PF1010 | PF1210 | PF1214 | PF1315 |

Belt Conveyor | B500*7M | B650*7M | B650*8M | B800*8M |

Configuration of wheels | Double axle | Double axle | Three axles | Four axles |

Generator | Selectable | Selectable | Selectable | Selectable |

Capacity(t/h) | 30-100 | 56-120 | 65-180 | 81-220 |

Power(KW) | 70-90 | 128.5-150.5 | 154-190 | 210-297 |

Feed Opening Size(mm) | 400*1080 | 400*1080 | 400*1430 | 860*1520 |

Max.Feed Size(mm) | 350 | 350 | 350 | 500 |

Dimension(L*W*H)(mm) | 12500*2800*6000 | 12500*3000*3500 | 13500*3000*6500 | 14000*3200*6800 |

Weight(T) | 42 | 46 | 51 | 57 |

Production Process of Mobile stone impact crusher

The big stones in the stone production line are coarsely crushed in the jaw crusher sent by the vibrating feeders through the bunker evenly. The coarsely crushed stones are sent to the impact crusher by the belt conveyor for further crushing. After tertiary crushing, the materials are screened in the vibrating screen through the belt conveyor to classify several sizes of stones. The stones which can meet the requirements will be sent to the finished product material piles by the belt conveyor, while the left stones will be sent to the impact crusher for another further crushing to form a closed circuit cycle. The finished product can be classified and combined according to the customers' needs. The dust removal equipment can be added in order to protect the environment.

A. Feeding system

This system is to paragraphs crusher equipment and the sieving machine for the raw material, according to the crushing screening process. Complete feed link devices have vibrating feeder or other types of feeding equipment. In the sand and gravel production line, are generally used for feeder equipment was responsible for the supply of stone.

B. Crushing system

The system is the heart of the whole equipment. Its job is to break all kinds of mineral raw materials into the size of the finished product, a joint sand and gravel production line can have more than one of crusher. The broken mechanical properties different from stone crushing work together.

C. Sieving conveyor system

Next step, broken of the ore by sieving machine for screening. In the application of compound production line, sand and stone need to be separated, and classification of ballast need transport to the respective sites. This process is the equipment used is generally linear vibrating screen or other screening equipment.