![[field:title/]](/templets/moban/imgcssjs/hot-sale-stone-cone-crusher-machine31062841766.jpg)

Hot Sale Stone Cone Crusher Machine

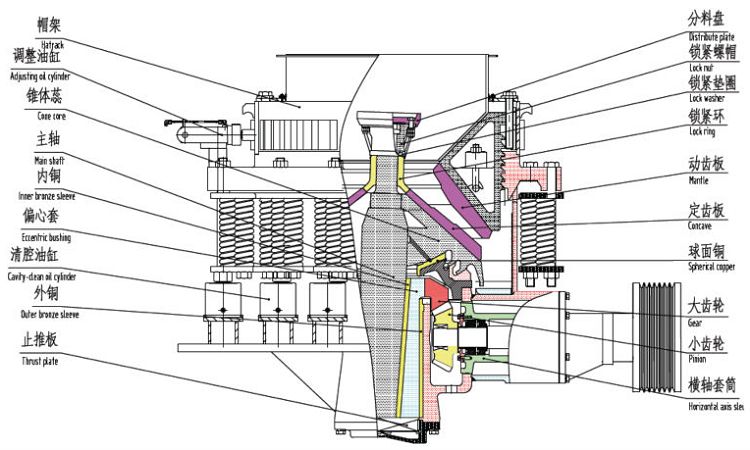

PY Cone Crusher Product Description Compared with jaw crusher, PY cone crusher has the advantage of low operation costs, high productivity, easy adjustment and stable structure. Cone Crusher can be used for secondary and fine crushing of hard and medium hard mineral stone, such as iron ore,...

Product Description

The cone crusher can be used for secondary and fine crushing of hard and medium hard minerals such as iron ore, copper ore, quartz, granite, basalt and dolomite. The spring safety system of the spring cone crusher can be used as an overload protection system to prevent the cone crusher from being damaged by metal. The dry oil-water seal form of the safety system is adopted to separate the plaster and the oil to ensure reliable performance.

Technical Data

|

Model |

Cone Diameter Mm(feet) |

Max. Feed Size(mm) |

Discharge Opening (mm) |

Capacity (t/h) |

Motor Power (KW) |

Specification (r/min) |

Weight (t) |

Overall Dimension (L*W*H)(mm) |

|

PYB900 |

900 |

115 |

15-50 |

50-90 |

55 |

333 |

11.2 |

2692*1640*2350 |

|

PYZ900 |

900 |

60 |

8-20 |

20-65 |

55 |

333 |

11.2 |

2692*1640*2350 |

|

PYD900 |

900 |

40 |

5-15 |

15-50 |

55 |

333 |

11.3 |

2692*1640*2350 |

|

PYB1200 |

1200 |

145 |

20-50 |

110-168 |

110 |

300 |

24.7 |

2790*1878*2844 |

|

PYZ1200 |

1200 |

100 |

10-25 |

42-135 |

110 |

300 |

25 |

2790*1878*2844 |

|

PYD1200 |

1200 |

50 |

5-15 |

18-105 |

110 |

300 |

25.3 |

2790*1878*2844 |

|

PYB1750 |

1750 |

215 |

25-60 |

280-480 |

185 |

245 |

50 |

3910*2894*3809 |

|

PYZ1750 |

1750 |

185 |

15-30 |

115-320 |

185 |

245 |

50 |

3910*2894*3809 |

|

PYD1750 |

1750 |

85 |

8-15 |

75-230 |

185 |

245 |

50 |

3910*2894*3809 |

|

PYB2200 |

2200 |

300 |

30-60 |

590-1000 |

280 |

220 |

80 |

4622*3302*4470 |

|

PYZ2200 |

2200 |

230 |

15-30 |

200-580 |

280 |

220 |

80 |

4622*3302*4470 |

|

PYD2200 |

2200 |

100 |

10-18 |

120-340 |

280 |

220 |

81.4 |

4622*3302*4470 |

Advantages

1.It's easy to operation and stable performance

2.Easy to maintain, reducing downtime and maintenance costs.

3.With higher capacity and less wear costs

4.Wide range of applications, suitable for various crushing needs

5.Laminated crushing, the material is good grain shape

How To Clean Crusher Machine

As a commonly used crushing equipment, the correct use and maintenance of crushers is an important part of equipment management work.

In the actual production process, many customers do not pay attention to the cleaning work of the crusher when using it, but if it is not cleaned, it will affect the operation of the equipment and expand the maintenance cost of the equipment. Therefore, the cleaning work is also an important part of the maintenance of the crusher. The cleaning of the crusher mainly includes four aspects:

-

Clean the crusher belt

-

Clean the inlet and outlet of the crusher

-

Clean the interior of the crushing cavity

-

Clean the outside of the crusher

Packing and Shipping

It can be packaged according to customer requirements. If there is no additional instructions, it is generally used to pack the machine with PP foam. The machine and accessories are reasonably arranged in wooden boxes and then shipped to the port in a unified container.

Port:Xiamen Fujian

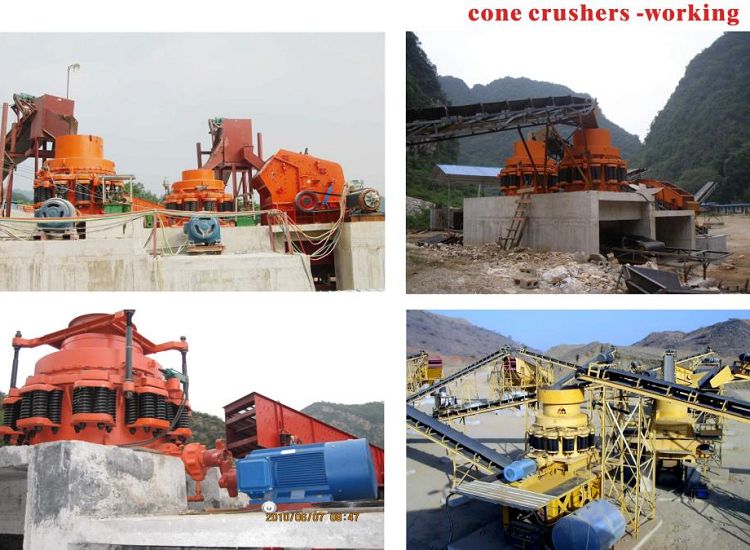

Project of company

Company Information

Persisting in customer-oriented, Mesto takes researching and manufacturing products that can satisfy customers as own duty, inheriting the development concept of “high-end mating and green growth” for the purpose—to focus on the high-end mating in the future, continuous efforts to create to provide clients with high-tech content and high value-added products and solutions. We provide our clients with a whole series of crushing and screening equipment, including high-end impact crusher, combined cone crusher, vertical impact crusher, vibrating screen and sets of gravel and sand production line.