![[field:title/]](/uploads/allimg/c211020/1634EH3009540-31304.jpg)

High Pressure Mill Price

Description High-pressure suspension grinder is widely used in mining, metallurgy, chemical industry, building materials and other industries. It can finely grind more than 280 materials with Mohs hardness less than 9.3 and moisture less than 6%. The particle size of the finished product is...

Description

High-pressure suspension grinder is widely used in mining, metallurgy, chemical industry, building materials and other industries. It can finely grind more than 280 materials with Mohs hardness less than 9.3 and moisture less than 6%. The particle size of the finished product is controlled at 80-80 425 mesh. Some special devices are added. , Can produce 30-80 mesh coarse powder.

Parameter

Name | Capacity(t/h) | ||||||

1.5-6.5 | 3-12 | 5-20 | |||||

Model | Power (kw) | Model | Power | Model | Power (kw) | ||

Main engine | Host machine | YGM9517 | 37 | YGM4121 | 75 | YGM160 | 132 |

Analytical engine | YGM9517 | 5.5 | YGM4121 | 7.5 | YGM160 | 11 | |

Draught fan | YGM9517 | 37 | YGM4121 | 75 | YGM160 | 132 | |

Auxiliary Machines | YGM9517 |

| YGM4121 |

| YGM160 |

| |

Dust removing equipment | YGM9517 |

| YGM4121 |

| YGM160 |

| |

Controller | Jaw Crusher | PE200×350 | 7.5 | PE200×400 | 15 | PE250×750 | 22 |

Bucket Elevator |

| 3 |

| 4 |

| 4 | |

Feeder |

| 0.2 |

| 0.2 |

| 0.2 | |

Eontroller Cabinet | Special use | YGM9517 | 90.2 | YGM4121 | 176.7 | YGM9517 | 301.2 |

Working Principle

In the main frame, a 1000-1500kg high-pressure spring is fixed on the roller hanger. After the grinding machine is put into use, the ring is affected by the high-pressure spring and centrifugal force. Under the same power condition, its rolling pressure is 1.2 times that of a Raymond grinder, and the output power is increased. When loading materials into the mill cavity. Shovel it into the space between the roller and the ring for grinding. The produced powder is sent to the separator along the circulating air of the blower, the standard fine powder is guided to the cyclone collector as the final product, and the large-size material falls back to the pulverizer for regrind.

The rough material will be recirculated through air to the grinding chamber for regrind. The material may contain some moisture and the pipe joints are not absolutely sealed, so outside air may be drawn in, which can disturb the air circulation balance, but can be achieved by adjusting the air tube between the blower and the main unit. In this way, excess airflow will be introduced into the baghouse, collecting the airborne powder and purging it to remove excess air.

Picture

FAQ

Q1: Are you trading company or manufacturer?

A: We are factory.

Q2: How long is your delivery time?

A: Generally it is 7-10 days if the goods are in stock. Or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q3: What is your payment method?

A: 30% of total prices should be paid by T/T as down payment; 70% balance payment should b paid by T/T before delivery.

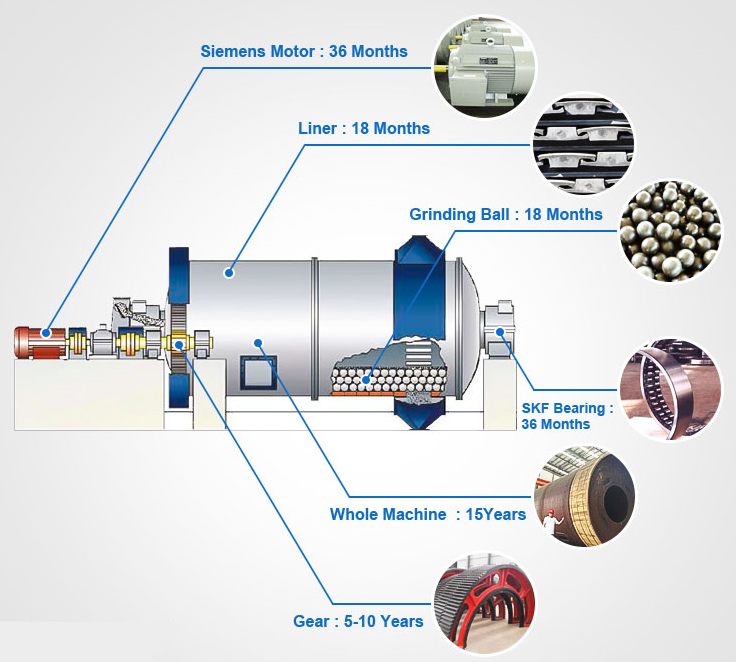

Q4: How long is the warrenty of your equipments? Does your company supply the spare parts?

A: The warranty period of crusher equipments is one year. And we will supply the spare parts for you at lowest cost.

Q5: If I need the complete crushing plant can you help us to build it?

A: Yes, we can help you set up a complete crushing line and give you related professional advices as long as you need. We had already build many mining projects in China & Overseas.