![[field:title/]](/uploads/allimg/c211020/1634EM6446210-S018.jpg)

Rock Crusher Factory

rock crusher machine Introduction : ZW vibrating feeder is mainly used for conveying big materials evenly to the coarse crusher. At the same time, it utilizes the effect of the bars or mesh to screen the dirt and fine-grained material. They are widely applied in metallurgy, mining, building...

rock crusher machine Introduction:

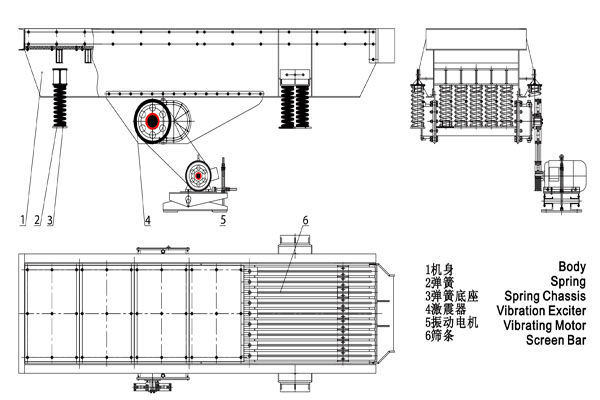

ZW vibrating feeder is mainly used for conveying big materials evenly to the coarse crusher. At the same time, it utilizes the effect of the bars or mesh to screen the dirt and fine-grained material. They are widely applied in metallurgy, mining, building material, silicate, chemical and abrasive industries of crushing and screening combined operations.

rock crusher machine Operation principles:

ZW Vibrating Feeder mainly consists of vibrating frame, spring, vibrator, motor vibrating, motor and other components. The vibrator is made of two specific eccentric shafts whose gears are jogged, and when installation, the two gears must be jogged according to the sign. Through the drive of the motor, the two eccentric shafts start to rotate, and producing a liner huge power which forces the feeder to vibrate. By the vibration, the materials will slip and sling on the funnel, moving forward. When the materials pass the screening part, the smaller parts will fall down from the gap of the screening part, avoiding the next crushing, and then finally reach the purpose of pre-screening.

Model | Hopper dimensions(mm) | Max feeding size(mm) | Output (t/h) | Power(kw) | Weight | Overall dimensions(mm) |

ZW-800*3000 | 850*3000 | 400 | 80-120 | 1.5*2 | 3895 | 3100*1800*1600 |

ZW-960*3800 | 960*3800 | 500 | 120-210 | 2.2*2 | 3980 | 3850*1950*1630 |

ZW-1100*4200 | 1100*4200 | 580 | 200-430 | 3.7*2 | 5570 | 4400*2050*1660 |

ZW-1100*4900 | 1100*4900 | 580 | 280-500 | 5.5*2 | 6520 | 5200*2050*1700 |

ZW-1300*5200 | 1300*4900 | 650 | 450-600 | 7.5*2 | 8200 | 5200*2350*1750 |

Our Services

Pre-sales:

*Help customers to choose product.

*Freely send engineers to the working field to plan the installation site and design the best technical production process.

*Design the special product according to the contract.

After-sales:

*Send the engineers to guide the installation.

*Install and adjust the equipment for customers.

*Train the operator for customers.

*We also provide the technical service for our customers after the installation.

*Solution for you choose as well as we will give lifetime free technical support and services.