![[field:title/]](/uploads/allimg/c211020/1634EW0C3310-9D19.jpg)

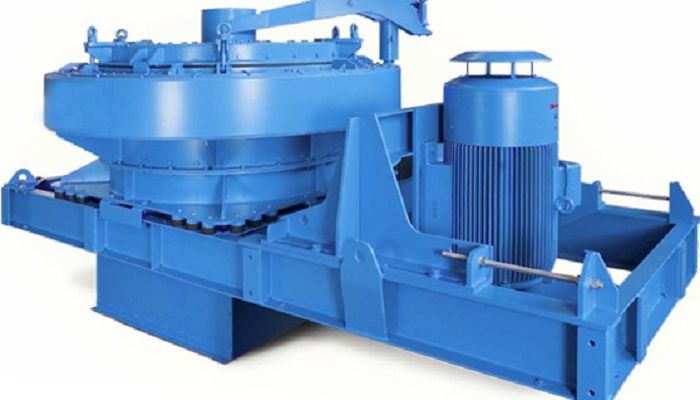

Rotor Centrifugal Crusher

MR Rotor Centrifugal Crusher Rotor Centrifugal Crusher Product Description MR rotor centrifugal crusher is a high performance of vertical crusher. it applies to all types of mineral crushing and shaping: material from soft to hard material. the material of both low wear and high wear. Each...

MR Rotor Centrifugal Crusher

Rotor Centrifugal Crusher Product Description

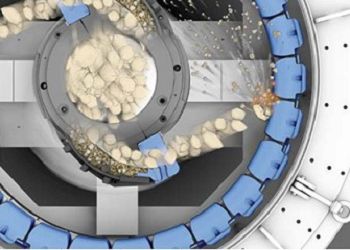

MR rotor centrifugal crusher is a high performance of vertical crusher. it applies to all types of mineral crushing and shaping: material from soft to hard material. the material of both low wear and high wear. Each particle in the material in the high speed rotating rotor double cavity, slammed to counterattack plate fixed. Counterattack plate can be made of annular plate or consists of a sand bed. Through the large size of the rotor and shell design to a great extent, to avoid the jams. And the big advantage is the whole rotor system sand machine welding parts, all wear protection for a single replaceable parts. Compared with multiple cavity design, MR rotor centrifugal crusher with double cavity of the rotor in the conveying air less and to reduce the energy consumption and save energy can be used to increase production capacity, but also reduce the power of the dust removal device. Double rotor cavity with open architecture design, allowing the discharging mouth of the maximum available size (89) on each side. This significantly reduce the risk of material jam. In MR double rotor cavity along the crushing cavity can form a layer of material, can be used as its own wear protection. Compared with the traditional rotor. the wear ratio fell to a minimum.

Rotor Centrifugal Crusher Product Features

• High quality of the final product Produce the high quality cubic shape products, Use centrifugal force to make every feeding grain get the great accelerated speed The casted materials crush with crushing plate.

• The quality stable's final product Even if the equipment in operation cause abrasion continually, also doesn't affect the material's crush effect. The system features can avoid the random-effects by material crushing . This is MR rotor centrifugal crusher's technology characteristics different from other traditional’s.

• Targeted selective crushing For each material particles through targeted shock crushing, The low intensity component materials is easier crushed then high intensity component. In this way, it can remove the easy crushing part's materials on purpose, thus, significantly improve the quality of the final product (wear value. freezing resistance).For the different intensity of components of ores and industrial minerals, can get the largest number's final product.

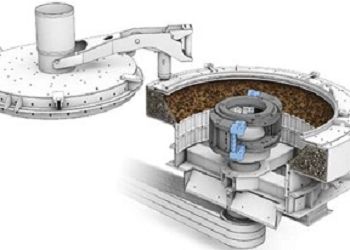

The annular plate structure of Rotor Centrifugal Crusher

• It is suitable for medium abrasion resistance material production cubic stone and sand making, such as Gravel limestone, dolomite, diabase, basalt, andesite, brick bat cement clinker etc.

• Selective crushing mud gravel and other conglomerate, medium abrasion resistance material of slag and industrial mineral, topsoil, etc.

• Recycling asphalt , unreinforced concrete block and construction waste, etc.

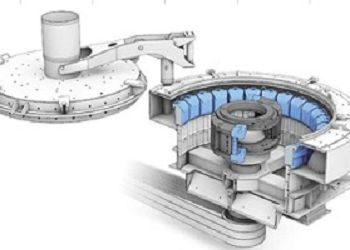

The sand bed structure of Rotor Centrifugal Crusher

• It is suitable for high abrasion resistance material production cubic stone and sand making, such as Gravel, granite and porphyry, gneiss, miscellaneous sandstone, quartz, etc .

• Crushing high abrasion materials, such as Aluminium vanadium and soil, ferrosilicon, abrasive , glass, etc

• Selectively crushing slag from steel plant, incinerator etc.

Rotor Centrifugal Crusher Technical Data

Model | Speed(m/s) | Max. Feed Size(mm) | Capacity(t/h) | Power (KW) | Weight (t) | Overall Dimension (L*W*H)(mm) |

MR-132 | 60-89 | 45 | 30-50 | 132 | 7.5 | 4200*1988*1870 |

MR-160 | 60-89 | 45 | 40-60 | 160 | 7.8 | 4200*1988*1870 |

MR-200 | 60-89 | 50 | 55-80 | 200 | 8.3 | 4200*1988*1870 |

MR-250 | 60-89 | 50 | 75-100 | 250 | 11.6 | 4200*2400*1980 |

MR-315 | 60-89 | 55 | 100-120 | 315 | 12.1 | 5200*2400*2150 |

MR-400 | 60-89 | 55 | 120-150 | 200*2 | 13.5 | 5200*2400*2150 |