![[field:title/]](/uploads/allimg/c211020/1634EUF013P-3bJ.jpg)

High Efficiency Jaw Crusher

Product Description Main Features * All kinds of model available; * Stable and reliable operation; * High reduction ratio; * Uniform-sized finished products; * Easy to maintain; * Low operating cost; * Deep crushing chamber; * Wide size range of discharging opening; * The machine has a better...

Product Description

Main Features

* All kinds of model available;

* Stable and reliable operation;

* High reduction ratio;

* Uniform-sized finished products;

* Easy to maintain;

* Low operating cost;

* Deep crushing chamber;

* Wide size range of discharging opening;

* The machine has a better performance with the hydraulic coupling.

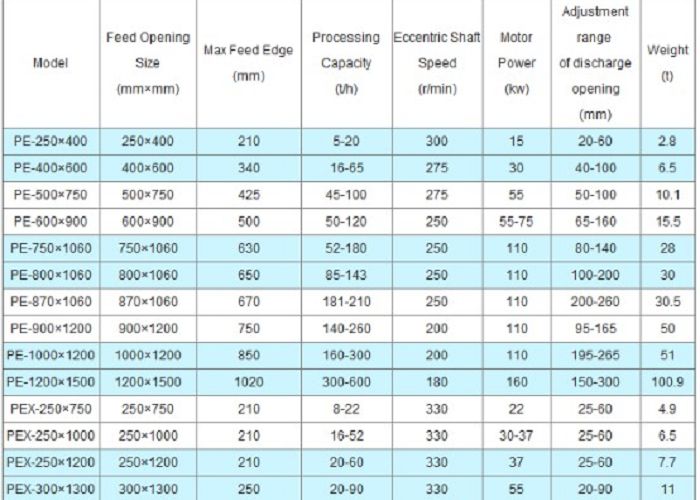

Technical Parameter

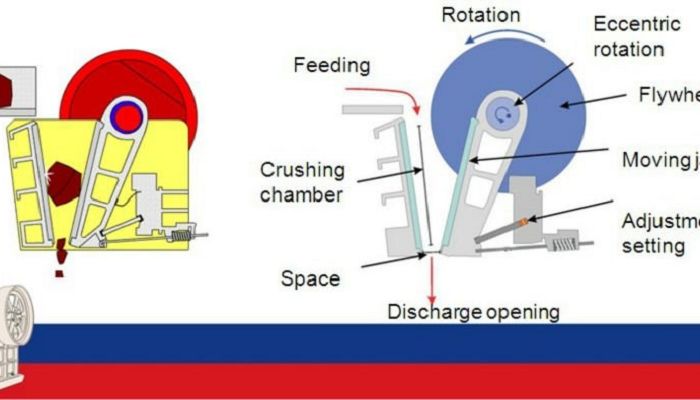

Working Principle

Jaw crusher machine is easy to install, operate and maintain. The working principle of jaw crusher machine is very simple. The whole crushing process rely on the relative motion of the two jaw plates——Fixed jaw plate and Spring jaw plate. The fixed jaw plate stay still while the spring jaw plate against it. And with the movement, the materials between the two plates would be crushed into small elements. While the plates move against each other, the materials would be crushed and while plates move away from each other, the broken materials which are smaller enough would drop through the discharging opening. There are two types of jaw crusher: PE and PEX.

Product Application

Jaw crusher is ideal for primary and secondary crushing, and is widely used in mining, quarry, ore, metallurgy, building, highway, railway, construction waste processing, water conservancy and chemical industry, etc. The jaw crusher is capable to crush mineral ores, rocks, and slag with crush strength less than 280Mpa. And size of materials fed in the stone jaw crusher should be equal or smaller than the maximum feeding size described in the following technical data.